Product Details

Swing welding head

Swing welding head

The process that traditional magnetic head cannot complete, the swing welding head only needs to use 70% of the power, which can save the cost of the laser.

In addition, the swing welding method, the width of the solder joint is adjustable, and the depth of fusion is strong, which makes up for the small shortcomings of the laser solder joint.

The tolerance range and weld width of the processed parts are enlarged, and a better weld forming effect is obtained.

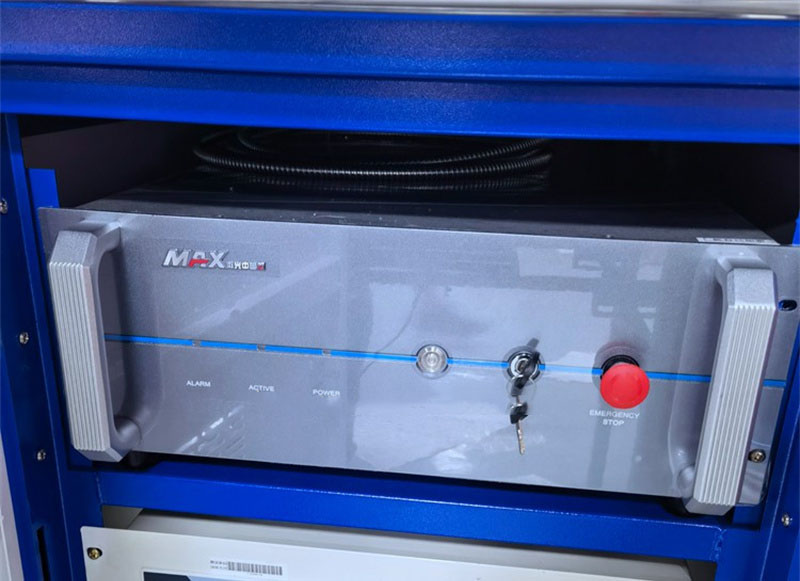

Brand laser generator Built in water chiller

IPG, JPT, MAX, Raycus laser generator optional. Dual temperature and dual control, circulating water

Laser power: 1000W , 1500W , 2000W circuit, can quickly cool the internal pipeline cavity of

dfdfgfdgbdfgfdgfgdfg the welding head, while cooling the laser.

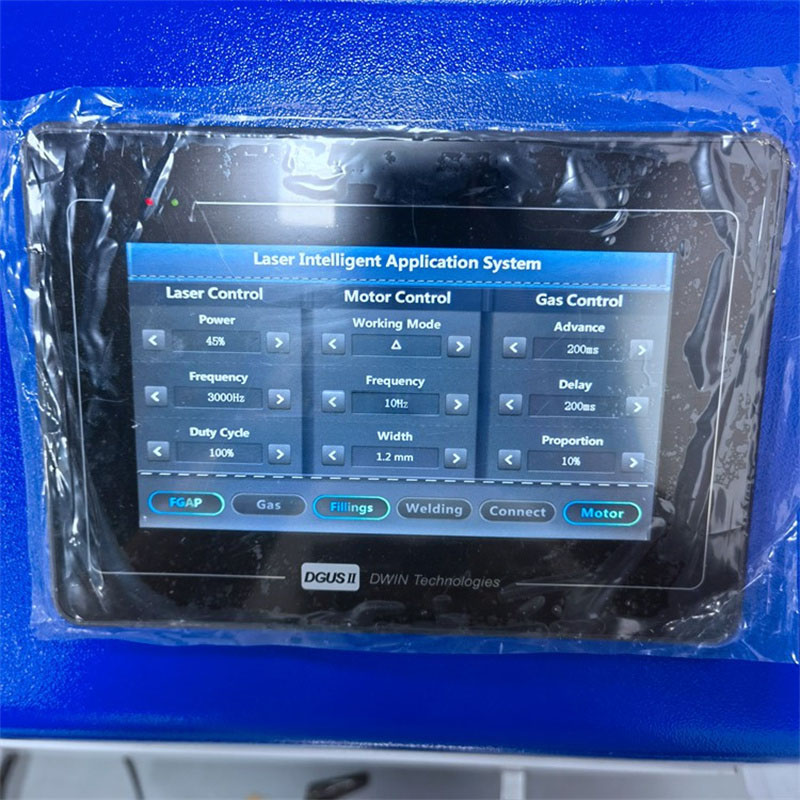

Intelligent control system Automatic wire feeder

Intelligent control system, touch screen, easy to set Automatic wire feeder, can set delay feeding, feeding

parameters. Has a variety of welding swing mode to speed, pumpback speed, pumpback time etc

meet different needs, get better welding effects

Optical fiber and handheld welding head support Simple operating panel

Place the fiber and hand-held welding head to avoid Display operation interface, simple and eye-catching

collision damage button, no programming and teaching, simple operation

ererggg

Merkmale

Limitations of the welding of large metal advertising characters, hand-held weld head overcome space.

Limitations of the welding of large metal advertising characters, hand-held weld head overcome space.Hand-held welding gun operating mode, can be welded to any angle of any part of the work piece.

Hand-held welded head is equipped with 10 m fiber, flexible and convenient can achieve outdoor welding.

Applicable to various complex welds, spot welding of various devices.

Easy to operate

Simple and easy to operate, no deformation of the welding seam, stable laser output to ensure welding consistency, high power density after laser focusing, fast speed, great depth and small deformation, 360-degree micro-welding.

Beautiful welding process

Breaking through the limitations of the original workbench, it is suitable for all kinds of complex welding seams, and it is easy to weld any part of the work piece at any angle. The humanized design and technology upgrade can weld beautiful welding seams.

Small body, efficient welding

The welding speed of laser welding machine is 3-10 times that of traditional argon arc welding and plasma welding. The welding heat affected area is small, and it will not cause problems such as deformation, blackening, traces on the back of the joint construction, and the welding depth is large, the melting is sufficient, and the welding is firm.

Dual-drive handheld swing laser welding head

There are 6 welding modes and multiple welding nozzles to meet different welding needs; it has a safety sensor function, which emits a laser after touching the metal and automatically locks the light when it is removed; the spiral jitter function, the width of the weld can be adjusted, and the welding ability is significantly improved.

360° No dead angle micro welding

After the laser beam is focused, a small spot can be obtained, which can be accurately positioned, and is applied to micro and small workpieces that are automatically produced in large quantities. Mainly for the welding of thin-walled materials and precision parts, it can realize spot welding, stitch welding, tailor welding, sealing welding, etc. High aspect ratio, small weld width, small heat aff

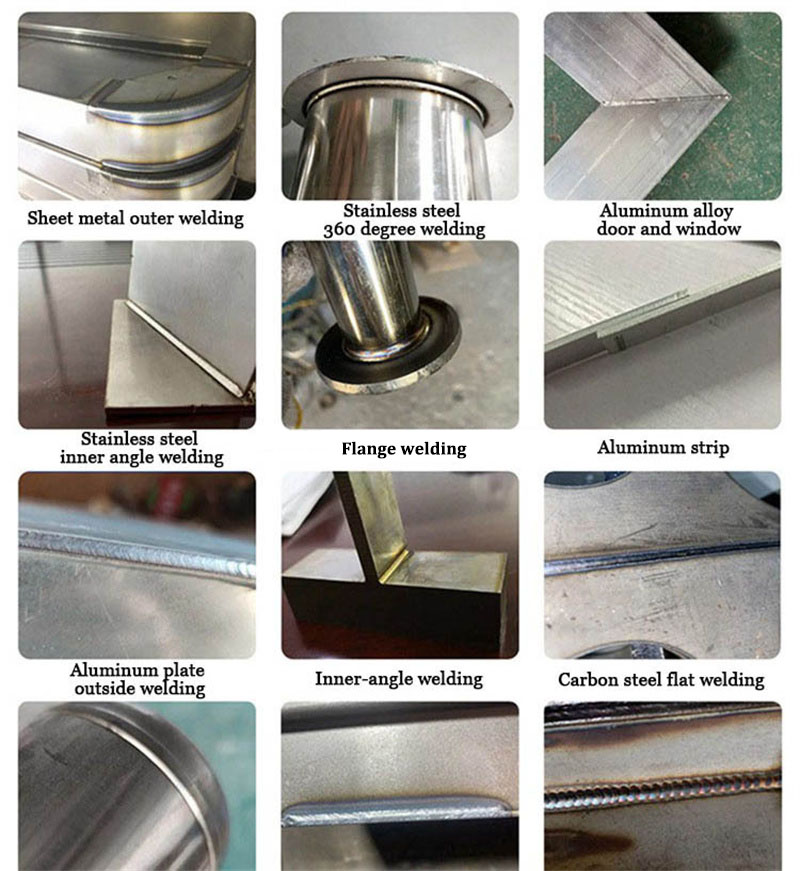

Anwendung

Handheld Fiber Laser Welder Applications

Verwendet zum Schweißen verschiedener Edelstahl-Spiegelzeichen, Edelstahl-gebürstete Zeichen, Edelstahl-Kugelzeichen, Edelstahl-Farbzeichen, Edelstahl-Sprühzeichen, Edelstahl-Massivzeichen, Edelstahl-Galvanisierungszeichen, Edelstahl-Goldfolienzeichen, Präzisions-Edelstahlzeichen, Flache Titan-Schriftzeichen, Kugelförmige Titan-Schriftzeichen Werbewörter, Seiko Titan-Gold-Schriftarten, Flache Kupfer-Schriftarten, Kugelförmige Kupfer-Schriftarten, Rote Kupfer-Schriftarten, Rote Kupfer-Antik-Schriftarten, Seiko Aluminium-Schriftarten, Metallfarbe-Schriftarten (Edelstahlstreifen, Eisenstreifen, kohlenstoffarmer Stahl Streifen) und Metallschriften werden zu Form geschweißt. Beleuchtungs- und Formenindustrie, optoelektronische Kommunikationsgeräte, Medizintechnik, Elektronik, Kupferteile, Aluminiumteile und kleine Schweißverarbeitungsindustrien.